The Best Strategy To Use For American Plastics

Everything about American Plastics

Table of ContentsExcitement About American PlasticsThe Main Principles Of American Plastics The Ultimate Guide To American PlasticsRumored Buzz on American PlasticsThe smart Trick of American Plastics That Nobody is Talking About

Bigger jobs may require pipes with higher sizes to effectively disperse liquids over long distances. Factors such as surface problem, the capacity for environmental tension, and the installation environment must influence the pipe dimension to ensure an effective, long lasting application.

Involve with expert guidance to validate your choice and adapt as essential for optimum results. Armed with this knowledge and the actionable actions outlined, you are fully equipped to make educated decisions when picking HDPE pipeline sizes for your projects. Your focus to information in this selection process will go a lengthy method in guaranteeing the efficiency, safety and security, and cost-effectiveness of your piping systems.

Everything about American Plastics

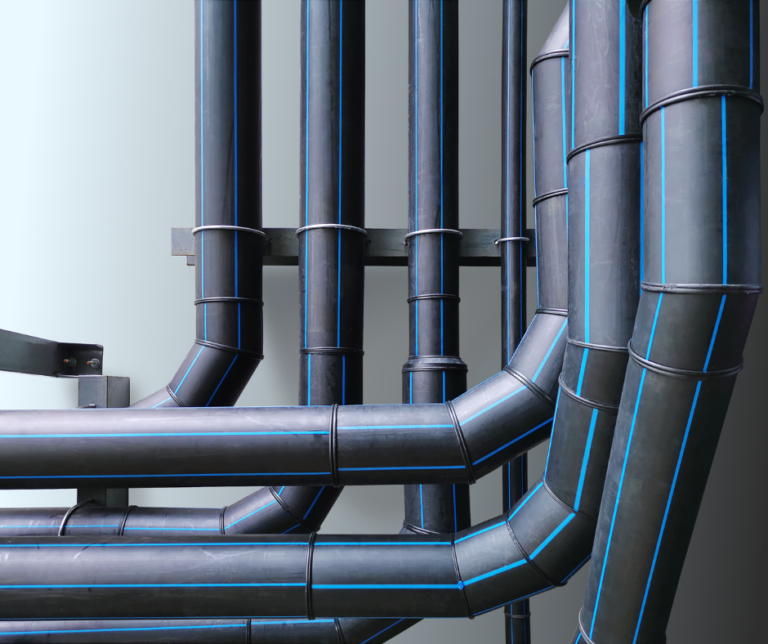

HDPE pipelines are extensively embraced across a range of sectors due to their flexibility and stamina. One of the most common uses for HDPE pipeline is in water supply systems.

: HDPE pipelines are joined via warmth combination, creating a smooth, uniform link as strong as the pipe itself. This leak-proof joint is essential in gas and water distribution, where leakages could bring about unsafe scenarios or expensive waste.: HDPE pipes are lighter than typical metal pipelines, making them much easier to carry and set up.

Our basic and rapid purchasing procedure and effective logistics guarantee you receive your 4-inch HDPE pipe in the quickest feasible time (HDPE Pipe for Oilfield). Our after-sales team is readily available 24/7 to aid with any kind of problems you might encounter, making certain peace of mind.

PE 80 is for basic commercial applications like gas and water, while PE 100 supplies lasting toughness and efficiency for harder uses. For a succinct take a look at applications, below are a few of one of the most common sorts of HDPE piping and their applications. Piping systems use PE 32 or PE 40 for low-pressure applications.

The 45-Second Trick For American Plastics

PE 80 has a product resistant to splits, so it's suitable in applications vulnerable to fracturing, like sewer system and water circulation lines. PE 100 is additionally resistant to cracks, and 100 N/mm2 is the minimum necessary stamina. As mentioned, categories of HDPE piping include nominal stress, material, and shade coding.

Suppliers create pipelines with different stress grades (PN qualities). This shows the pressure in bars the pipe can sustain with water at 68 levels Fahrenheit. The pressure qualities comply with European criteria, and they are: PN 2.5 max stress 2.5 bar PN 4max stress 4 bar PN 6max pressure 6 bar PN 10max pressure 10 bar PN 16max stress 16 bar The color codes that indicate the stress grade are yellow for PN4, red for PN6, blue for PN10, and green for PN16.

The full checklist of dimensions is substantial. Pipeline distributors offer sizing guides with additional info like wall surface density and mass. Quality assurance complies with ISO requirements managing the product style and minimum required stamina (MRS) of pipes. Normally, quality control tests inform the manufacturers if the HDPE pipes can offer 50-plus years of service under normal operating problems.

Industries think about small stress, material, and various other elements when identifying which pipelines to use - https://giphy.com/channel/americanplastics. Today, you'll see high-density polyethylene pipes in water supply, gas circulation, agriculture, and a lot a lot more.

The Ultimate Guide To American Plastics

It's worth noting that gas calls for high tolerance to pressure, making PN-16 to PN-2 quality informative post pipes suitable for operations. The agriculture sector makes use of HDPE pipes for irrigation and drain.

Mining business utilize pipes for slurry transport and dewatering. HDPE piping can protect cables in the telecom market. This is advantageous for underground wires. The very best component is that organizations can utilize general PN course pipelines for this application. Industries pick HDPE piping over standard pipes since they offer extra benefits.

For beginners, HDPE pipelines are exceptionally long lasting and can last a long period of time with very little maintenance. They're additionally resistant to deterioration, chemicals, and UV rays. https://peatix.com/user/27822559/view. HDPE pipes are additionally affordable contrasted to other piping products. They're less vulnerable to damage, which cuts fixing costs! HDPE pipelines are lighter than traditional pipes for much better handling and transport.

Facts About American Plastics Uncovered

Whether you're a contractor, designer, or do it yourself fanatic, this short article will offer you with the expertise to make enlightened decisions and achieve ideal outcomes. When it concerns selecting the appropriate HDPE pipeline for your job, recognizing the PSI rating is of utmost significance. The PSI rating determines the strength and stress ability of the pipeline, indicating just how much stress it can endure without failing.

The PSI ranking of an HDPE pipeline establishes its capability to deal with various pressure degrees. Pipes with greater PSI scores can stand up to better pressure, making them appropriate for applications that include higher fluid or gas stress. On the other hand, pipes with reduced PSI ratings are optimal for low-pressure applications.